Styling

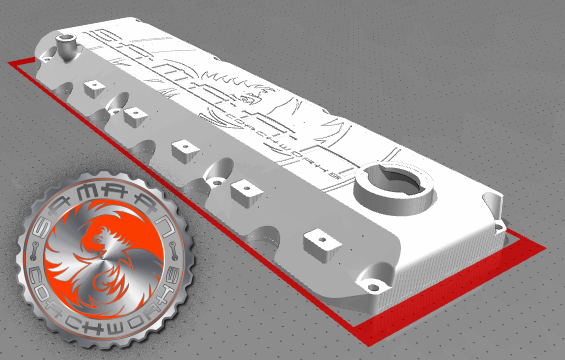

Samaan Coachworks: Custom M20 Valve Cover

As you read the various posts and pages in this website, you will come to understand that one of the prime motivating factors in the creation of Samaan Coachworks is the vast discrepancy between the styling available to European BMW owners and American BMW owners. One of the most attractive styling options of the Euro Alpina and Hartge variations on the BMW M20 and M10 engines was their valve covers.

As an Architect and Industrial Designer, designing a valve cover came to mind as I was learning to modify the BMW M20 at a local machine shop. One of the benefits of apprenticing at a machine shop and learning from the old-school engine builders was being able to rummage through their bins and pull out the worn or broken engine components. I sandblasted select components and cut them apart; dissected them so I could understand what the BMW engineers were thinking.

I did this with engine pistons of all makes and models; broken and no longer usable BMW cylinder heads went under the band-saw and cut at various intervals in order to inspect the geometries of the aluminum castings. Old and broken BMW OEM valve covers were cut apart as well, and once their design was understood, careful measurements were taken, and these measurements became the basis for my own M20 valve cover design.

Like the IDF Manifolds, I have the choice of either printing these custom valve covers out of high-temp resistance 3D printing materials, casting them out of aluminum, or CNC routing them out of billet aluminum. Each material choice entails different design strategies because of the specifics of the various manufacturing processes. In order to design for these materials, you have to learn and understand what is and what isn’t feasible per process, and choose which one suits your budget and specifications best. This is where my decades of industrial manufacturing and design come in handy.